News

Read all the news!

Sheet metal forming: what it is, when it is needed

OTIM SRL is perfectly equipped to perform deep drawing operations on sheet metal, making use of a competent and prepared staff, which uses only the best technology in the sector.

Differences between stamping and punching

The OTIM SRL company in Pedrengo (BG), in business since 1971, deals with blanking and drawing for third parties, using only the best professionals in the field, equipped with advanced technology.

Stamping tool design: why it’s important to use the right designer

Contacting OTIM SRL, a Bergamo-based company, means choosing a product that is developed starting from planning and drawing, thanks to the use of sophisticated equipment, operated by a technically competent staff.

Sheet metal stamping: why clearance calibration is so important

The OTIM SRL company, in Via Gattamelata n. 2/4, in Pedrengo (BG), specialized in sheet metal shearing works, has always paid great attention to clearance calibration operations.

The stages of designing a die for sheet metal

The precision with which a mold is made is essential for the success of sheet metal processing, because only in this way will the company be able to deliver to the customer a finished product that complies with the instructions provided in the preliminary phase of the agreement.

Stamping, namely giving the metal its shape

Our company deals with molding, implementing a strategy that follows every phase of the production process, from the design of the molds for metal to the realization of the final product.

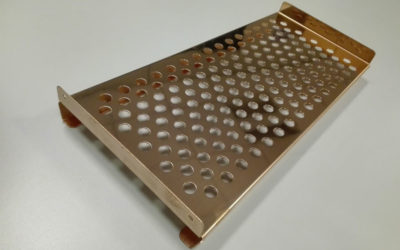

Finishing, edging, galvanizing… a short guide to the various metalworking processes

The OTIM SRL company wants only the best for its customers and that is why it pays particular attention to final procedures such as finishing, edging and galvanizing.

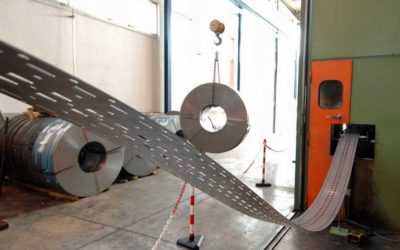

Transfer die or progressive die?

Transfer and progressive molds have important differences, so much so that the decision about the adoption of one or the other model rests with a competent and qualified technical office, based on the final result required by market demand.

Why is pre-stamping metal sometimes necessary?

There are some metal stamping jobs where precision is paramount: in these cases, nothing can be left to chance. An optimum way to ensure quality work is to carry out pre-stamping, followed by actual stamping.

Mechanised area for projection welding of sheared components

https://youtu.be/noXWrm-nz-c A mechanised area is inserted for the projection welding of sheared components. The machine loads the parts on a first station then welds them and deposits them in the box.The system is integrated with the management system of the company...