Let’s discover together what is involved

Stamping, as with deep drawing, are metal working processes that allow the deformation of a metal sheet plastically, using a special die, designed and manufactured to make the entire production cycle possible.

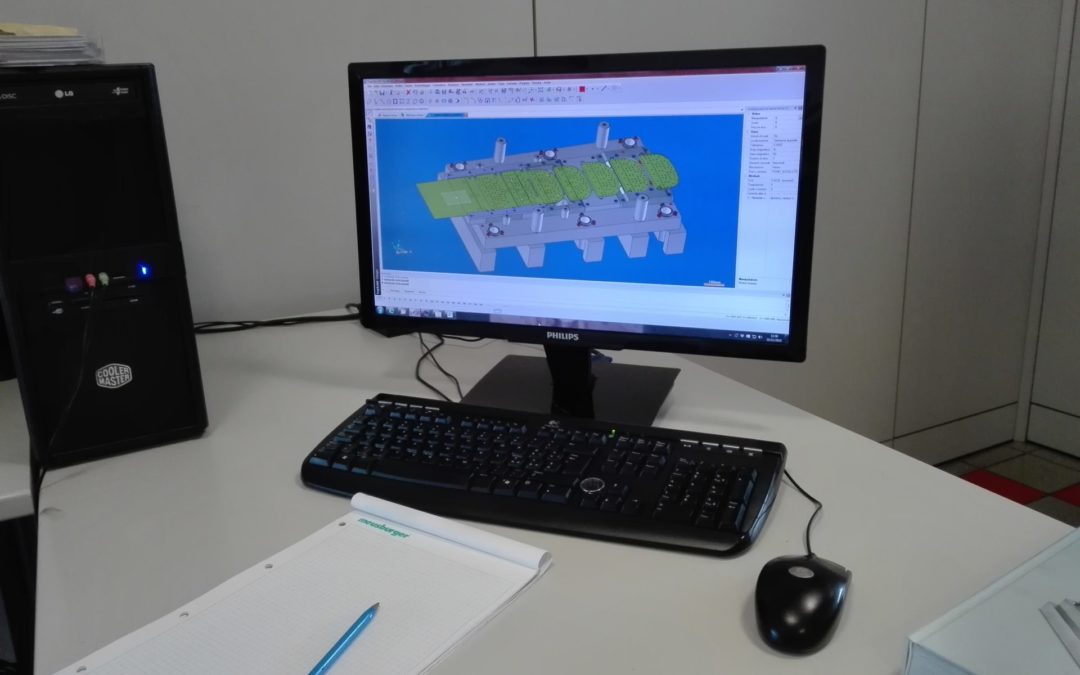

This consideration explains the specific attention given to the design of the molds in question, which must be suitable for the purpose.

In this sector, the most successful dies are, without doubt, the transfer die and the progressive die.

Both made of sheet metal, the two types have important and clear differences, so much so that the decision, about the adoption of one or the other model, is up to an expert and qualified technical department, based on the final result required by market demand.

The company OTIM SRL, in Via Gattamelata n. 2/4, a Pedrengo (BG), provides the customer with a professional and experienced staff, which has gained, over the years, the experience necessary to direct clients on the work that best suits their needs.

The transfer die

This specific die is part of the group of dies for stamping and offers the user a large number of advantages.

First of all, it is necessary to underline that the peculiarity of this particular transfer die consists in its ability to simplify the production cycle, since it allows the company to produce, using a single machine, pieces that normally need more reworking.

Even the complexity of the shapes is mitigated by the use of the transfer die, capable of satisfying even customers with very specific technical and aesthetic requirements.

The mould works by means of a transfer mechanism that is not directly connected to the main structure, since it is a sort of accessory to combine the pair press-mould.

In fact, the transfer consists of two fundamental elements, called “little hands”, mounted on two aluminum bars and created to support the experts during the movement of the pieces along the die, in between each operation.

The type we are talking about is particularly suitable for complex productions, also for a simple question of the ease of maintenance, under certain conditions.

However, it is important to pay attention to one fact: the transfer die was created to be bound to a specific production machine and, if the company decided to move the die, this would cost a large amount of money

The progressive die

The progressive die was created to allow workers to perform operations on a roll of sheet metal.

Each time the press is activated, the progressive die can produce, simultaneously, one or more pieces, depending on the specifications of the production cycle.

Regardless of the type of work carried out, more than one operation can be carried out, without the piece coming off the strip.

The part, in fact, moves along the die by means of a carrier, leaving the hooking mechanism only at the end of the entire process.

Unlike the transfer die, the progressive die is equipped with different die blocks and different punches, allowing the company to adapt the system to different types of presses.

In essence, several individual stations are tasked with modifying the piece, with heterogeneous operations, capable of supporting even high volumes of intervention.

In this way, the production cycle will be optimized, ensuring the operating company low costs and high hourly yields.

OTIM SRL knows that every choice of this kind must be calibrated, after careful preliminary technical analysis on the particular type of production to be carried out.

To find out more about this topic and to get in direct contact with the company’s staff, interested parties can contact the number +39 035 661234.

Recent Comments